This free small engine repair course is designed for beginners, offering a comprehensive guide to maintenance, troubleshooting, and repair of small engines, perfect for homeowners and DIYers.

1.1 What is a Small Engine?

A small engine is a compact, portable power source used in various outdoor equipment like lawn mowers, generators, and trimmers. Typically two or four-stroke internal combustion engines, they are designed for efficiency and versatility. This course focuses on understanding and maintaining these engines, ensuring optimal performance and longevity through proper care and repair techniques.

1.2 Importance of Small Engine Maintenance

Regular maintenance is crucial for extending the lifespan and efficiency of small engines. Proper care prevents premature wear, reduces repair costs, and ensures reliable performance. This course emphasizes routine tasks like inspecting systems, cleaning, and lubricating to keep engines running smoothly and avoid unexpected breakdowns, essential for both professionals and DIY enthusiasts.

1.3 Benefits of Learning Small Engine Repair

Learning small engine repair empowers individuals to perform routine maintenance and fixes independently, saving money and time. It enhances problem-solving skills and provides a deeper understanding of engine mechanics. This knowledge is valuable for homeowners, landscapers, and professionals, enabling them to keep equipment running efficiently and extend its lifespan. It also fosters self-reliance and confidence in handling mechanical tasks.

Overview of the Free Small Engine Repair Course

This free course offers a comprehensive guide to small engine repair, covering maintenance, troubleshooting, and repair techniques through detailed instructions and illustrations, ideal for homeowners and professionals.

2.1 Target Audience

This course is ideal for homeowners, landscapers, and DIY enthusiasts seeking to learn small engine repair basics. It also benefits professionals in related fields, offering practical skills for troubleshooting and maintenance, ensuring peak equipment performance through hands-on training and detailed guidance.

2.2 Learning Outcomes

Upon completing the course, learners will understand the basic principles of small engine operation, including inspection, routine maintenance, and troubleshooting; They will gain practical skills in diagnosing common issues and performing repairs, ensuring optimal equipment performance and longevity through hands-on training and detailed guidance.

2.3 Course Structure and Modules

The course is divided into clear, modules covering essential topics such as basic engine principles, fuel and ignition systems, cooling, lubrication, and exhaust systems. Each module is designed to be comprehensive and easy to follow, with detailed instructions and illustrations to guide learners through practical applications and troubleshooting techniques.

Key Modules in the Course

The course covers basic engine principles, fuel and ignition systems, cooling, lubrication, and exhaust systems, providing a foundational understanding of small engine operation and maintenance.

3.1 Basic Principles of Small Engine Operation

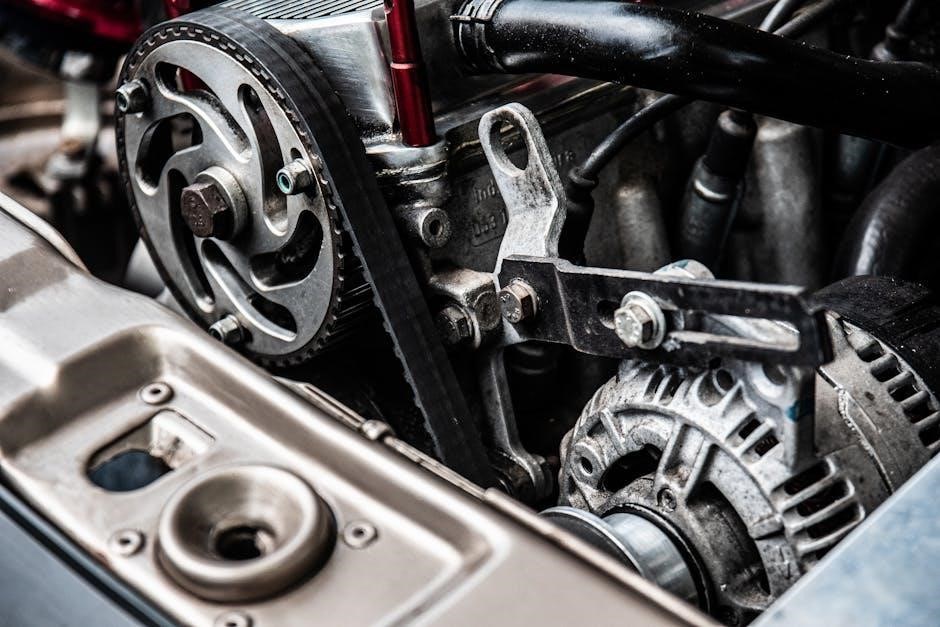

This module introduces the fundamental concepts of how small engines function, including the four-stroke and two-stroke cycles, combustion processes, and the role of key components like pistons, crankshafts, and valves. It explains how air, fuel, and spark interact to produce power, ensuring a solid understanding of engine operation. Practical examples and diagrams help learners apply these principles to real-world small engine applications, such as lawn mowers and generators.

3.2 Fuel and Ignition Systems

This module covers the essential components of fuel and ignition systems in small engines, including carburetors, fuel tanks, spark plugs, and ignition coils. It explains how fuel is delivered and ignited, emphasizing the importance of proper air-fuel mixtures and spark timing for efficient combustion. Troubleshooting techniques for common issues like poor starting or rough running are also explored, ensuring learners can diagnose and repair fuel and ignition-related problems effectively.

3.3 Cooling, Lubrication, and Exhaust Systems

This module explores the critical roles of cooling, lubrication, and exhaust systems in small engines. It explains how cooling systems prevent overheating, lubrication ensures moving parts run smoothly, and exhaust systems manage emissions and pressure. Troubleshooting techniques for common issues like overheating, oil leaks, and blocked exhausts are also covered, helping learners maintain engine efficiency and longevity.

Tools and Materials Needed

Essential tools include screwdrivers, wrenches, and multimeters. Materials like filters, gaskets, and lubricants are crucial. Safety gear such as gloves and goggles is also necessary.

4.1 Essential Tools for Small Engine Repair

Essential tools include pliers, punches, and chisel sets for disassembly. Compression testers and carburetor cleaning brushes aid diagnostics. Ignition testers and multimeters are vital for electrical systems. A well-organized toolbox and a sturdy workbench are indispensable. Proper tools ensure efficient repairs and prevent engine damage. Always refer to manufacturer manuals for specific tool recommendations.

4.2 Safety Equipment and Precautions

Always wear safety glasses, gloves, and steel-toe boots when working with small engines. Ensure the workspace is well-ventilated to avoid inhaling fumes. Disconnect the spark plug before disassembling the engine to prevent accidental startups. Use jack stands for added stability when working under equipment. Keep a fire extinguisher nearby and avoid wearing loose clothing that could catch in moving parts. Safety precautions protect both you and the engine.

Troubleshooting Common Issues

Identify common problems like engine failure to start, poor performance, or overheating. Learn to diagnose root causes and apply practical solutions to restore functionality effectively.

5.1 Identifying and Diagnosing Problems

Learn to systematically identify and diagnose common issues in small engines. Start with visual inspections, checking for dirty air filters, faulty spark plugs, or uneven fuel flow. Use diagnostic tools like compression testers to assess internal engine conditions. Understand how to analyze symptoms such as rough running, overheating, or failure to start. This module emphasizes practical techniques to pinpoint root causes efficiently, ensuring effective repairs and minimizing downtime.

5.2 Simple Maintenance and Repair Techniques

Master essential maintenance and repair techniques for small engines, including cleaning or replacing air filters, checking spark plugs, and inspecting fuel lines. Learn basic repair skills like adjusting carburetors and replacing worn-out parts. This section focuses on practical, cost-effective methods to keep your engine running smoothly, emphasizing safety and proper tool usage for DIY success.

Advanced Topics in Small Engine Repair

Explore advanced techniques like engine disassembly, precision adjustments, and complex troubleshooting. Ideal for those with mechanical experience, this section dives deeper into specialized repair methods and tools.

6.1 Disassembly and Reassembly of Engines

Mastering the disassembly and reassembly of small engines is a critical skill. This module provides detailed, step-by-step guidance, ensuring proper handling of components, alignment, and torque specifications. Learners gain hands-on experience, understanding how to safely dismantle engines, inspect parts, and reassemble them efficiently. Visual aids and practical exercises enhance comprehension, making complex procedures manageable for advanced learners.

6.2 Precision Measurements and Adjustments

Precision measurements and adjustments are vital for optimal engine performance. This module teaches learners to use tools like micrometers and dial indicators to ensure accurate component fitment. Proper adjustments prevent wear and tear, enhancing engine longevity and efficiency. Clear guidance helps learners master critical tolerances, ensuring precise repairs and maintaining peak engine operation. Practical exercises reinforce these advanced techniques, essential for skilled engine repair.

Safety Guidelines and Best Practices

Always wear personal protective equipment like gloves and safety glasses. Ensure proper ventilation and avoid loose clothing near moving parts. Follow manual instructions carefully to prevent accidents.

7.1 General Safety Tips

Always ensure good ventilation when working with small engines to avoid inhaling harmful fumes. Keep loose clothing and long hair tied back to prevent accidental entanglement. Avoid wearing jewelry that could catch on engine parts. Ensure the workspace is clean and well-lit to reduce tripping hazards. Never work on an engine while it is running or hot. Test simple solutions first before disassembling the engine.

7.2 Personal Protective Equipment (PPE)

Wear safety goggles or glasses with side shields to protect eyes from debris. Use gloves to prevent cuts and abrasions. A dust mask is essential when handling dirty or dusty components. Steel-toe boots or sturdy footwear can prevent foot injuries. Ensure long sleeves and pants are worn to avoid skin exposure. Keep hair tied back and avoid loose jewelry to minimize risks during repairs.

Resources for Further Learning

Recommended books include Chilton’s Guide to Small Engine Repair and Small Engines & Outdoor Power Equipment. Online forums and communities offer additional tips and troubleshooting advice for learners.

8.1 Recommended Books and Manuals

Key resources include Chilton’s Guide to Small Engine Repair and Small Engines & Outdoor Power Equipment. These manuals provide comprehensive guidance on maintenance, troubleshooting, and repair, designed for learners with little mechanical experience. They feature detailed instructions and illustrations to simplify complex concepts, making them invaluable for both beginners and experienced enthusiasts seeking to refine their skills.

8.2 Online Communities and Forums

Online forums like Fixmylawnmower.com and community college platforms offer valuable support for learners. These spaces provide access to expert advice, troubleshooting tips, and shared experiences. They also host discussions on course materials, helping users deepen their understanding and stay connected with peers and instructors. These resources complement the free course, fostering a collaborative learning environment for small engine repair enthusiasts.

Practical Projects and Applications

Hands-on projects involve repairing small engines, such as lawn mowers, and applying course knowledge to real-world scenarios, enhancing skill development and practical understanding of engine mechanics.

9.1 Hands-On Projects for Skill Development

Hands-on projects, such as repairing lawn mowers and trimmers, allow learners to apply theoretical knowledge. These exercises focus on troubleshooting, routine maintenance, and component replacement. Real-world applications enhance problem-solving skills and confidence. Each project is designed to reinforce learning, ensuring practical understanding and mastery of small engine repair techniques.

9.2 Real-World Applications of Course Knowledge

Course knowledge enables learners to perform routine maintenance, diagnose issues, and repair small engines in real-world scenarios. Skills gained can be applied to lawn mowers, chainsaws, and generators. By mastering these techniques, individuals can save money, extend equipment lifespan, and enhance self-sufficiency. Practical applications empower learners to tackle everyday challenges confidently and efficiently, making the course highly valuable for homeowners and professionals alike.

Frequently Asked Questions

This section addresses common queries about the course, such as prerequisites, duration, and certification. It also provides tips for maximizing learning outcomes and troubleshooting effectively.

10.1 Common Questions About the Course

Participants often ask about prerequisites, course duration, and certification. The course is designed for beginners, requiring no prior mechanical experience. It offers flexible learning with downloadable PDF modules. Certification is provided upon completion, enhancing DIY skills and confidence in repairing small engines effectively. The course structure ensures comprehensive understanding through practical examples and step-by-step guides.

10.2 Tips for Successful Learning

Engage fully with the course material, following step-by-step guides and practicing hands-on tasks. Apply knowledge by working on real engines to reinforce concepts. Start with simple repairs and gradually tackle more complex projects. Ask questions and seek help when needed to clarify doubts. Set realistic goals and dedicate consistent time to learning. Use safety equipment and follow guidelines to avoid injuries. Regularly review materials to retain information effectively and explore additional resources for deeper understanding.

Completing the free small engine repair course empowers you with essential skills to maintain and repair engines confidently. Apply your knowledge by working on real-world projects and sharing your expertise with others. For further growth, explore advanced repair techniques, specialized tools, and professional certifications. Stay updated with industry trends and continue learning through additional resources and hands-on practice to master small engine repair.